Fridges, AC demands, logistics, storage, manufacturing and cost management

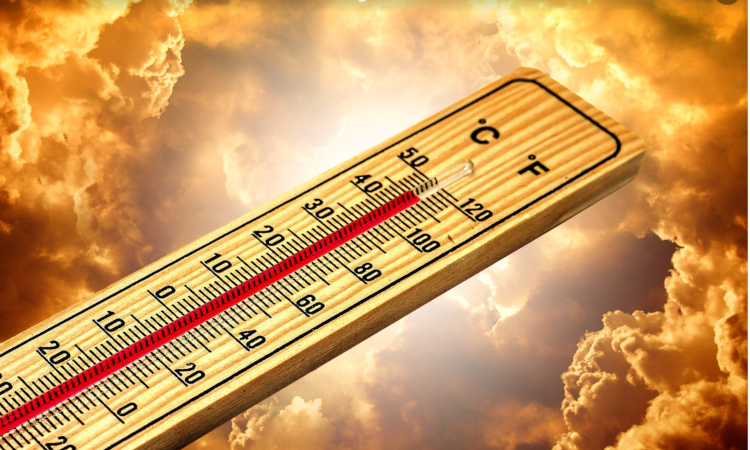

As temperature continues to keep breaking record high, so does the sales for machines that keep everyone cool, from fridges to keep beverages cold to AC to keep the house from being too hot to live in.

These machines takes time to manufacture, takes cargos and cargos to ship from origin of manufacture to their destinations, not only time, the whole logistic and manufacturing chains are affected if demand is suddenly out of expected, so having a forecastable demand would reduce client’s wait time, increase sales, reduce logistic costs(purchasing sea freight cargo spaces ahead of time) and many other benefits.

“Exceeding 240,000 Million Units, Air Conditioning System Sales Swiftly Rise at 6% CAGR, through 2031”- https://www.prnewswire.com/news-releases/exceeding-240-000-million-units-air-conditioning-system-sales-swiftly-rise-at-6-cagr-through-2031-fact-mr-301344134.html

“A new record for AC sales this year, with prices rising up to 15%”https://pkbnews.in/a-new-record-for-ac-sales-this-year-with-prices-rising-up-to-15/

In countries that are especially hot, the demands for these machine will increase exponentially, as a lot of growing countries are located on the equator, thus the demand for these units will increase in a rate that will be out of our expectations, and industries that are related such as recycling the AC units, refrigerator units and safety deposes of the coolant, to reduce the environmental impact to minimal as possible. Pre-arrange all logistics chain processes to reduce the impact and wait time from sea freight shipping as possible as we saw the logistic crisis and cost/ inflation impact it had on the economy in late 2021 and 2022.